I’m not sure I follow. You do this in N scale? Mind posting a photo please?

Thanks, Otto

Here you go...

This is the point rails and throwbar for an HOn2 (7mm gauge) Code 55 #7 turnout. The tiny hinge plates (on the throwbar) are laser cut from 0.006" thick steel and have a tongue that goes under the stock rails. The throwbar is a length of 1/32" thick x 0.060" wide PC tie stock from Clover House.

Untitled

Untitled by

jeffB, on Flickr

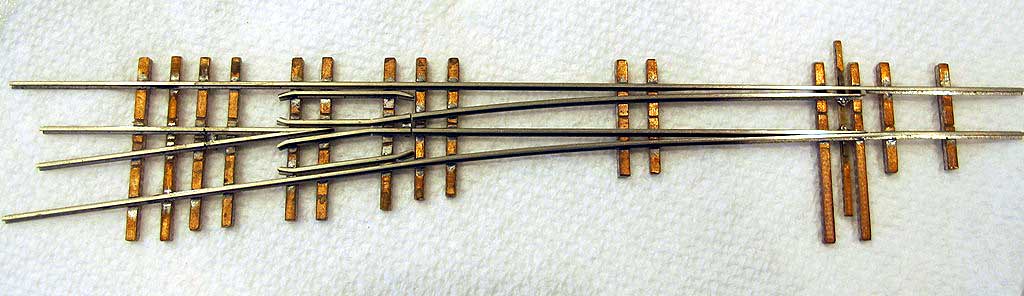

If you're curious... Here's a photo of the turnout itself. It's rather old and dusty because I decided to stick with HOn30 instead of HOn2. The point and frog rails were filed using a Fast Tracks Point Form tool, but the rest of the fixtures are of my own design. The frog assembly fixture was machined on my mill and the rest of the fixtures were laser cut out of various thicknesses of aluminum.

Untitled

Untitled by

jeffB, on Flickr

JB