I'm skipping a lot here and just summarizing.

It takes a lot of work to get the kits up and running well.

Consult the previous thread for full details. I'm not concerned with detailing yet nor DCC. I'm just getting them running.

But I made a couple of changes based on what I learned from the previous thread.

Here is a B Cab.

The shell is held by three screws through the walkway- as you can see. Here is my re-designed mechanism.

Here is the wiring harness I made.

That blue part is an analog plug. You can see the DCC coloring on the left. Rail power is the outside colors (red and black) and the inside pins are the motor leads (orange and gray).

The blue plug pulls out (to be replaced in the future with a decoder).

The red plug at the top goes to the front truck under the motor.

The rest remains with the motor permanently.

Here is how I made an analog plug.

When red and orange and the black and gray are paired together, you now have an analog loco.

Here you can see the jumpers.

Shrink wrap is added to cover the jumpers.

One more shrink wrap and a little superglue now makes an end that can be pulled on when removing the plug.

I also made a point to label parts. This is motor 4. And this goes in the B cab.

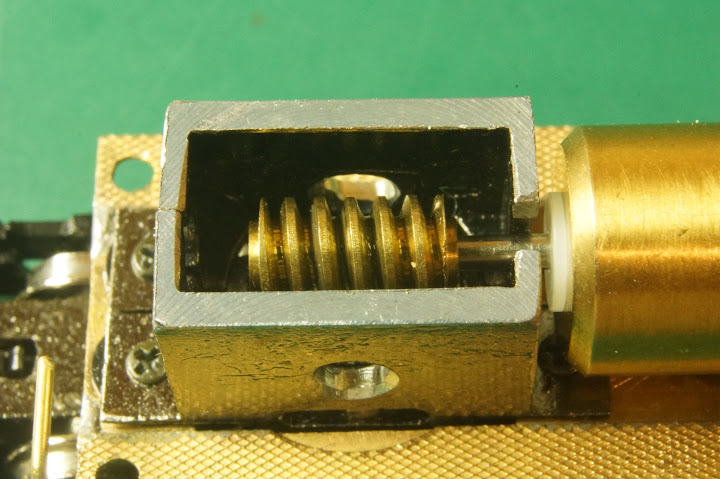

One of the most important mods I made was to cut a hole in the gearbox so that I could inspect the gear mesh with the worm. Getting this mesh perfect is key to performance.

Another important change was to add a bit of solder between the outer walkway and the main frame.

This I discovered is a weak spot. Those joints pop loose with handling. Adding extra solder gives them greater strength.

Not exactly beautiful, but the shell hides it.

That photo above shows a change I made since the last thread.

You can just see MicroTrains black truck washers under the gearbox.

By raising (shimming) the gearbox up, it actually LOWERS the walkway toward the truck.

Remember, this loco appears a little too high. I may or may not keep this later. It depends on what happens when I add my extra frame later.

But THIS is the best and most important change I made.

You can see that I cut a slot in the right edge of the gearbox.

This allows the motor shaft to slip out of the gearbox.

Consequently, I can now remove the motor WITHOUT disassembling the gearbox (a MAJOR hassle).

I cannot tell you how much better this makes loco servicing.

Now, one of the problems I had before was that in order to access those screws between the gearbox and the flywheel, I had to shift the flywheel as far over to the motor as possible AND use a very tiny screwdriver to get at the screws. But this made oiling the inner motor bearing a challenge.

But now, with that slot in the gearbox, NONE of this is a problem anymore.

I am able to move the flywheel away from the motor and cover the screws on the gearbox.

No problem-- I can just lift the motor out now.

THEN I can easily get at those screws.

Also, oiling the motor is VERY easy now.

To remove the motor, I just pull that red plug up top and remove those two screws on the back.

That is all.

Easy-peazy. I love it.