I took a few years to come up with another modular standard which owes a bit to Bendtrack, FreeMoN, and Ntrak. About a dozen of us locals here in Utah are running the standard (which we've named "F-Units") and we're pretty happy with it so far.

The differences between our new standards and the others is mainly that we emphasize big LDE's based on prototype scenes, AND operations. I like to say "We build big scenes for little trains."

The modular standards encourage an excellent scenery to track ratio, ease of viewing by the operators, actual "modeling" meaning hand-built turnouts, code 55 ME track, handlaid code 40 track, LDE's based on prototype scenes and trackwork and lots of scratchbuilt structures that the local residents recognize. Also Digitrax Radio DCC to allow easy growth and running the occasional DC powered train, makes it all run excellently.

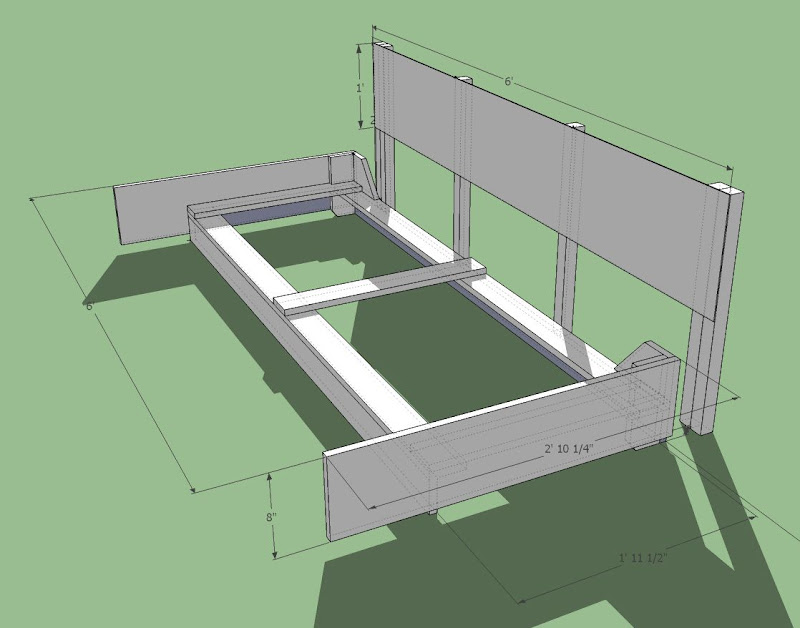

The stats are these: (1) Basic "unit" size is 6'X3' which we believe is the maximum easily transportable dimension (2) Double L-girder benchwork construction with integral folding legs (3) 52" railhead to floor height (4) Required 14" skyboards (5) 24" minimum visible mainline radius (6) 18" absolute minimum not visible mainline radius and visible branchline radius (7) Low-pro wheelsets (

DCC wiring w/Anderson Powerpole connectors (9) all turnouts powered by Circuitron Tortoises (10) 6' minimum "unit" length (12) 12' minimum LDE length encouraged (13) minimum passing siding length of 9' 7.5" (14) 1.5 inches between mainline centerlines (15) double mainlines and provisions for single mainline branchlines (16) A minimum of two swing-arm drafting lamps with 27W 5000K compact fluorescents per 6' "unit"...and more.

Emphasis is on large scenes (some up to 36' long), operations, contiguous scenery based on actual places (Utah railroads), superdetailing and scratchbuilding.

The large size of the individual "units" takes advantage of N-scale's great scenery-to-track ratio but means the member needs a truck and/or trailer to bring his "units" to the shows. The back-to-back nature of setup (with a small operator's pit included in the design) means that there is a minimum of two "units" per member.

F-Units standards, combined with the club's standards establishes what is basically a home layout that goes to shows, and is designed to target more advanced model railroaders rather than appeal to the kiddies...who have a plethora of other clubs trying to please them with less serious stuff such as Spongebob Squarepants under the bridge over the kitchen sink, or the LEGO display.

Interestingly, crowds gather (we call this "schooling"...like fish) most when we're operating. Kids also like to see the locals do their jobs, and are not bored one whit with picking up and setting out cars. Of course there are always the small "walk-ins" who can't see the trains very well without Dad or Mom to pick them up. The moms and dads are happy to do that, which keeps the small ones from grabbing that $1,500 GTEL turbine as it's coming out of the tunnel. We also have several "viewing stations" for not-so-tall individuals to step up on.

Additionally, operations are from the front and the operators mix with the crowds very well. It's pretty easy to keep up a conversation, watch the signals, move the trains and talk at the same time. When it gets really crowded, we assign a couple of members to follow the operators around and they answer the question overflow.

Here are three pics of us set up at the Evanston Roundhouse Festival a couple of years ago:

This basic setup is comprised of "units" and modules built to two different exploratory standards, with adapters between us. To arrive at the final solution we built several different modules to different standards which were similar enough that height, width, fascia depth and skyboard setback were "adaptable" so with the help of our adapters, we didn't have to trash any of our work. Present construction is adhering strictly to the new "F-Units" standards. The two main differences from these sets of modules and F-Units' "unit" standards are module width and fascia depth.

Also, we do not actively recruit members. We welcome "apprentices" and part of the philosophy is to instruct those who wish to learn how the club does things and builds things. Two of the main areas of interest by apprentices are scenery and hand laying turnouts. I give regular clinics at my home about these subjects as well as others. Other members with their skills and talents are also involved. I also participate in design of track plans as well as assist members in constructing their "units" since I have a well-equipped wood shop. Several other members also are well-equipped with wood working tools.

Here's a 3D model of F-Units basic benchwork standards minus the folding legs and fascia attachment protocol:

I think all the different modular standards have their pluses and minuses (F-Units included) and I like many of the features that Bendtrack offers as well as the others. What I don't like about Bendtrack is the narrow width (which ignores one of the great things about N-scale...the scenery-to-track ratio), the miniscule 14 1/2" minimum mainline radius, and the table-top style benchwork that's recommended. I also don't like that the skyboard is optional. The reason people leave it off is because of the measly one foot minimum from the fascia face to the skyboard, so removing it doubles the visible real estate...but also reveals the other side of the loop. That's my main objection with FreeMoN too...the lack of a skyboard which draws your attention to the module details, separates the model from the rest of the world, and expands the effective horizon much further than just the edge of the fascia.

I also did away with those funky joiner track sections which both Bendtrack and Ntrak require. No need for 'em as long as the person building the modules can read a tape measure. After suffering through those myriad ski-jumps that Ntrak produces with their overabundance of lousy joiner tracks, not having them solves a lot of problems whereas having them just encourages misalignment. Doing away with them also gets rid of the "need" for code 80 Atlas track on the straights at module ends and also decreases the 6" straight requirement to only 2" or even less. If you think you need some leeway at module ends, then simply don't glue or nail down your flex for four inches on one track per side...or all of them even. That does the trick much easier, but I've found that's not really necessary either.

I do like the Ntrak DCC wiring standards however, and I incorporated most of them into F-Units' electrical standards except I was more specific about wire quality and type as well as what connectors to use.

If your group is not planning on joining up with any other group, then there's no reason for you to comply with every standard. The main thing that causes incompatibility is the railhead to floor height, as most other standards can be compensated for by constructing a couple of adapters, even the wiring, the number of tracks and track spacing. However, the Ntrak boys will not like the 14.5" minimum radius and a lot of equipment they run might have trouble with that, as well as some equipment your members might like to run. If you're serious about opting for the Bendtrack standards, I'd make sure the "balloons" on the ends have at least a 20" minimum radius which means the red line would require a 21.5" radius...which means that the balloon would be roughly a foot longer and a foot wider than the "minimum balloon" illustrated in the Bendtrack standards.

I'd also seriously consider widening the ends to at least 3' to give more depth...or maybe even 4'...or two 2 footers back to back to ease transportation.

With the jigs, fixtures, instructions and parts available from Fast Tracks and Proto87 Stores, I'd also trash the Bendtrack and Ntrak requirement to use ONLY commercial RTR turnnouts on mainlines. This requirement assumes that handlaid turnouts are worse than RTR turnouts which with the modern construction aids available nowadays is simply not true. In a club environment the expense of buying two or three (or more) sets of jigs and fixtures for your chosen turnouts and other track configurations would soon start saving you money and "unhook" you from the lack of availability that Atlas in particular (and their customers too) have suffered recently because of problems in China. You'll also find that hand laid turnouts are more durable, run better and can be repaired in place if there's a problem. Did I mention that they look better too? And...they're MUCH cheaper. The jigs and fixtures make them more uniform and inspire confidence to potential builders who might be intimidated by the thought of hand laying turnouts using simple paper templates...which I've done going on 4 decades now.

I'm 65, and for all my close-up model work, I'm now using Optivisors of varying strengths. However, I can still easily tell from more than three feet away what kind of track is being used, or whether the trains are rounding curves that are superelevated (or not). There's a huge difference in the appearance of modules that have funky joiner tracks and those that don't, and for us oldies, the 52" railhead to floor height is a significant enhancement both for viewing our trains, and having to get under the benchwork.

I suppose that's more than enough said, but I hope there's something in my modular experience that will benefit you and your group before you settle on a modular standard that's got compromises that you don't want or need.